ABOUT US

We originally started as a metal fabrication company, focused on manufacturing heavy-duty steel products such as roll-off containers, metal dumpsters, structural components, and tarp systems for trucks.

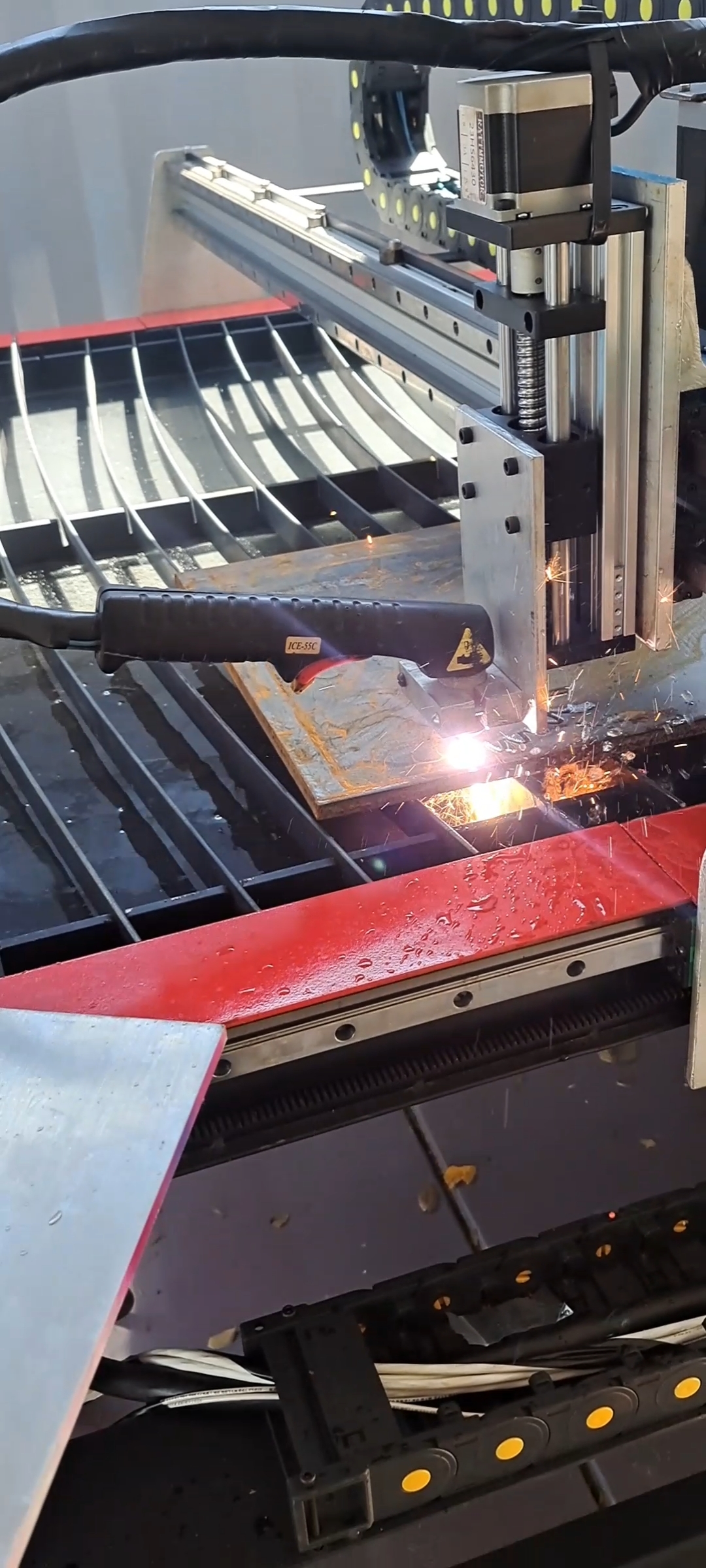

As part of our daily production work, we identified a clear need for a reliable CNC plasma cutting table. Instead of purchasing an expensive industrial machine or relying on low-cost systems with basic computer-based controls, we decided to design and build our own solution.

With a team of trained engineers and extensive hands-on experience in metalworking, welding, and industrial fabrication, we developed a CNC plasma table that has been operating flawlessly in real production conditions for over three years.

Through this experience, we realized something essential:

the people who use CNC plasma machines are usually fabricators, welders, and workshop owners who already know how to build steel structures.

We also understood that the most expensive parts of these machines are not the electronics or the controller — but the metal fabrication and shipping costs.

That insight led us to create our own CNC plasma system concept:

a fully assembled and pre-wired control and motion kit, combined with detailed fabrication drawings that allow workshops to build their own table structure locally.

This approach dramatically reduces cost while maintaining professional-grade performance.

Our clients can build a CNC plasma machine tailored to their workspace, material sizes, and production needs — using a dedicated industrial controller, without paying the price of a full commercial machine.

The result is a powerful, scalable, and affordable CNC plasma solution designed by engineers, tested in real workshops, and built for people who fabricate for a living.